17

Dec

What is Electrical Discharge Machining (EDM)?

EDM is a non-traditional manufacturing process that uses thermal energy to remove material from a workpiece opposed to mechanical force. Engineers often turn to EDM when machining processes such as CNC milling and turning cannot produce the desired cut for example, when there are sharp internal corners or a particularly deep cavity.

Types of EDM

Electric discharge machining can be divided into three common types, Die sinking EDM, Wire EDM and hole drilling EDM.

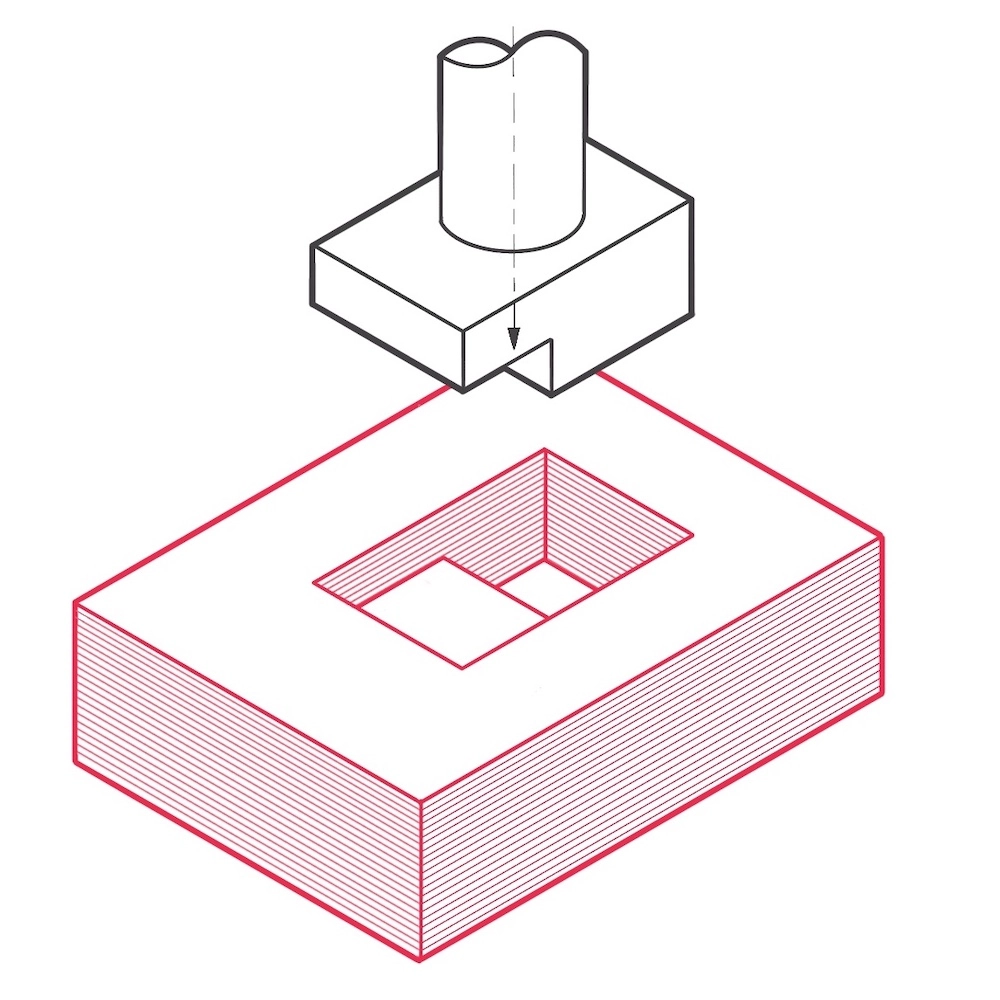

Die sinking EDM

Die sinking EDM or Ram EDM is an attractive option when complex cavities need machining. Firstly, a graphite electrode is produced in the reverse shape to the required cavity to form the die. The process works by inducing a voltage between the die and the electrically conductive workpiece while being submerged in a dielectric fluid. The die is slowly lowered towards the workpiece until ‘electric breakdown’ occurs and a spark jumps the ‘spark gap’. This vaporises/melts the material, and the dielectric fluid subsequently carries the ejected particles away. Material is repeatedly removed from the workpiece by a series of high-frequency sparks, precisely cutting out the desired shape.

Wire EDM

Wire EDM otherwise known as wire erosion, is commonly used for the production of extrusion dies. It cuts using the same mechanism as die-sinking, however, the die is replaced with a very fine electrically charged wire. This machining method is comparable to a cheese cutter, making a two-dimensional cut in a three-dimensional part. The cutting wire is burnt during the machining process so fresh wire is continuously replaced from an automated spool to ensure precise cutting. The diameter of the wire typically ranges from 0.05mm to 0.35mm.