Get in touch today to begin your additive manufacturing project.

Please see our How It Works video for more information about our simple, straightforward process.

Hong Kong Machining Services Inc. has the capability, capacity and expertise to produce bespoke 3D printed parts for a wide range of applications. With state-of-the-art machinery capable of producing both metal and plastic parts, Hong Kong Machining Services Inc. is your additive manufacturing partner.

Additive Manufacturing is the perfect solution for low volume, high complexity parts. Our partner factories produce exceptional parts at competitive prices. Simply tell us what you need then trust Hong Kong Machining Services Inc. to manage the whole process for you.

Vast capability

Competitive Pricing

Fast turnaround

ISO 9001 Quality Assured

Additive manufacturing (more commonly known as 3D printing) is a manufacturing process whereby parts are created by adding material gradually, layer by layer. This is in contrast to conventional subtractive processes where material is removed from a billet. Therefore 3D printing can result in lower material costs.

3D printing can also produce parts that were previously impossible to create using conventional methods allowing engineers to create increasingly complex parts and topologically optimised designs.

Hong Kong Machining Services Inc. has a range of Additive Manufacturing methods at our disposal including: Fused Deposition Modelling (FDM), Stereolithography (SLA), Selective Laser Melting (SLM) and more. Both metals and plastics are available. Contact us today to discuss your bespoke 3D printing requirements

CMM Reports

First Article Inspection Report

Material Certificates EN3.1

Tolerances: +/- 0.05mm Or Better On Request.

1 - 2.5 Weeks Lead Time For Complex Projects.

Delivered 2 days early on average.

With Hong Kong Machining Services Inc.’s unrivalled capability and access to state of the art 3D printing technology, trust Hong Kong Machining Services Inc. to deliver your additive manufactured project. Hong Kong Machining Services Inc. is also ISO 9001 accredited, ensuring quality throughout your interaction with us.

Perhaps you need to prototype parts before committing to your final design? Prototype and mass produce your parts under one roof with Hong Kong Machining Services Inc.’s wide suite of manufacturing processes.

Request a 24 Hour Quote

Please see the list for a sample of materials we work with for Additive Manufacturing. Plastics listed are available in a wide range of colours.

Looking for a material not listed here? Get in touch with us today to discuss your requirements.

Contact Us

24 HOUR QUOTE

| Plastics | Metals | Resins (SLA) |

|---|---|---|

| PLA | Stainless Steel | Standard |

| ABS | Aluminium | Clear |

| Carbon Fibre | Brass | Tough |

| PET-G | Bronze | Rubber |

| POM | Inconel 625 | Flexible |

| Nylon | Castable | |

| Flexible TPU |

Surface roughness can be specified using a Ra value.

Bead blast size: 80um as standard. 50-120um available.

Vapour polishing can providea glossy, smooth finish for certain plastics. Get in touch to find out more.

We have access to wide range of additive manufacturing equipment from the HongKong’s leading additive manufacturing suppliers. With an unrivalled range of state-of-the-art machinery, Hong Kong Machining Services Inc. has the capacity to meet any 3D printing request.

Not only will you receive personalised 3D printing support from our knowledgeable HongKong office, we will also provide feedback from our Additive Manufacturing experts from across the globe.

Our expert team can help advise your designs to avoid many 3D printing pitfalls. We welcome new 3D printing projects from new and existing clients. Start your project today!

Project Support

Fast Lead Times

Hong Kong Machining Services Inc. is proud to partner with the automotive industry and motorsports teams looking to gain a competitive edge over their rivals.

Discover more in our Case Study with Imperial Racing Green.

Hong Kong Machining Services Inc. continues to provide CNC machining services for the Film & TV industry, supplying bespoke camera parts and lens equipment.

Find out more in our case study with Sneek Films.

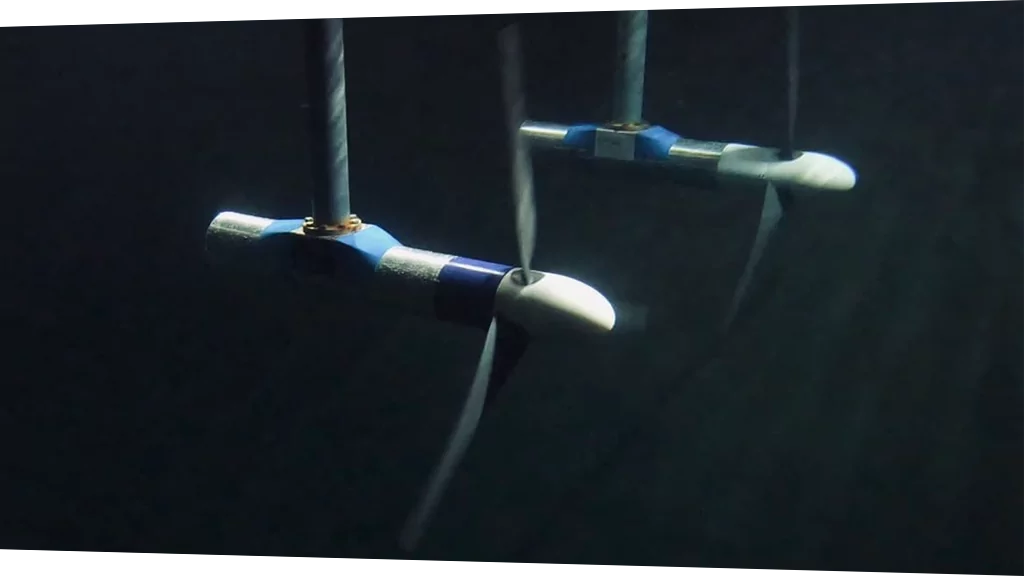

“ Hong Kong Machining Services Inc. is proud to supply leading HongKong Universities and scientific institutions with custom metal and plastic parts.

Read about how we helped a team from Oxford University manufacture cutting edge tidal turbines.”

Get in touch today to begin your additive manufacturing project.

Please see our How It Works video for more information about our simple, straightforward process.

Hong Kong Machining Services Inc. are at the top of their game when it comes to reliability and quality. We trust Hong Kong Machining Services Inc. to deliver parts on time and within tolerance. We can't speak highly enough of their customer service. Hong Kong Machining Services Inc. are quick to reply to enquiries and keep you well informed throughout the whole process.

Max Blake

Designer - Max Blake Design

The Hong Kong Machining Services Inc. team are very responsive and knowledgeable, fully owning a project throughout, providing superb communication. Transparent pricing structure and rapid quotation turnaround is by far the quickest I’ve experienced, reducing time to manufacture. Hong Kong Machining Services Inc. are a pleasure to work with.

Ollie Masters

Lead Process Engineer - Karakuri

Working with Hong Kong Machining Services Inc. for all our prototyping was an absolute pleasure. Next to immediate response, fast lead times, often arriving before the stated date. Their attention to detail and customer service were second to none, and all at the most competitive price point that couldn’t be beaten in the U.K.

Ben Coughlan

Director - Sneek Films Ltd

We initially started working with Hong Kong Machining Services Inc., as we needed a high quality product developed within a very short lead time. The entire process went very smoothly and we received the products ahead of schedule. We were pleased with the final results and we found working with Luke very easy, as he offered good technical advice.

Tom Butterfield

Designer - Tom Dixon