Find out more about our three-step process for getting your Metal Injection Moulded Parts manufactured in our How It Works video.

To begin your project, get in touch with one of our HongKong team today and we’ll get back to you as soon as possible.

Hong Kong Machining Services Inc. is your manufacturing partner for Metal Injection Moulding (MIM). Uniquely, we have no Minimum Order Quantity (MOQ) for metal injection moulded parts, although typically the process is suited for high volume production. Whatever your requirements, Hong Kong Machining Services Inc. has the capability and flexibility to deliver for your project.

With a range of secondary processes including CNC Machining, Hong Kong Machining Services Inc. is your go-to partner for your bespoke moulded parts. Trust Hong Kong Machining Services Inc. to manage your project and deliver your parts on-time, to specification and at a competitive price.

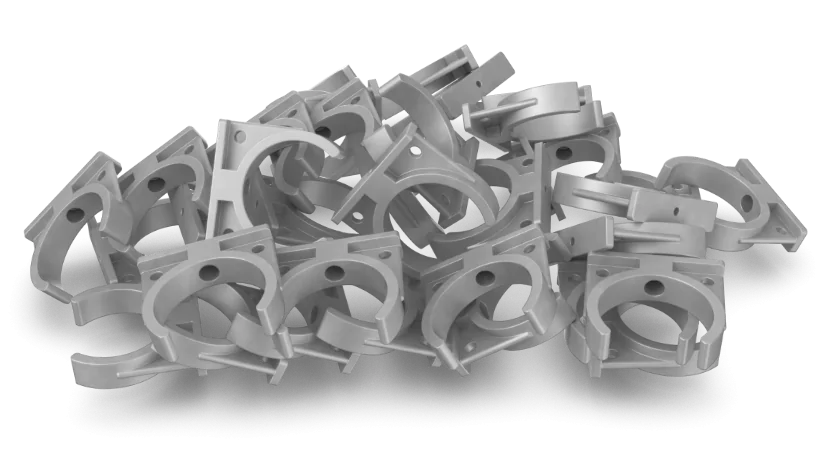

High Precision MIM Parts

Competitive Pricing

No Minimum Order Quantity

ISO 9001 Quality Assured

Metal Injection Moulding (sometimes referred to as MIM) is a casting process whereby a fine metal powder is mixed with a plastic binder and injected into a mould of the desired shape. This creates what is known as a ‘green part’. The binder is then removed to form a ‘brown part’ which is subsequently sintered to produce the final metal part.

Metal Injection Moulding allows for complex parts to be manufactured. It is best suited for smaller, high volume parts in which the costs and capabilities of other manufacturing processes would be prohibitive.

Hong Kong Machining Services Inc. has developed excellent contacts and knowledge in the expanding Metal Injection Moulding industry. Get in touch today to discuss your requirements and start your project.

Quality Assured:

CMM Reports

First Article Inspection Report

Material Certificates EN3.1

Tolerances: +/- 0.05mm Or Better On Request.

1 - 2.5 Weeks Lead Time For Complex Projects.

Delivered 2 days early on average.

Please see our list of common metals we use for Metal Injection Moulding. Please note, aluminium and zinc are not suitable for metal injection moulding; why not consider die casting? If you require a material not listed, get in touch with our expert team to discuss your requirements.

Contact Us

24 HOUR QUOTE

| Low Alloy Steels | Tool Steels | Stainless Steels | Magnetic Alloys | Other |

|---|---|---|---|---|

| AISI 4605 | M2 | SS316 | Fe-3%Si | Copper |

| S7 | SS304 | Fe-50%Ni | Titanium (6Al-4V) | |

| 17-4 PH |

The part will remain as machined with no further finishing processes.

Bead blast size: 80um as standard. 50-120um available.

Our partner factory in China offers precision Metal Injection Moulded parts and extensive tooling capabilities at an affordable price. With China’s extended working week, we can provide rapid leadtimes. We have spent years developing the perfect casting partner factory in China so you don’t have to.

Our HongKong manufacturing partners offer high quality metal injection moulded parts produced a wide range of specialist materials and the capability to follow your exact quality assurance procedures. With a strategic range of partners across the country, we have the capacity, capability and expertise to handle any manufacturing request.

Each project is expertly planned and managed from first quote to final delivery to achieve quality, efficiency and value. Our team will offer you a direct, personalised service; always on hand to answer any questions you may have about Metal Injection Moulding.

We always aim to respond to all queries within 24 hours.

Project Support

Fast Lead Times

Hong Kong Machining Services Inc. is proud to partner with the automotive industry and motorsports teams looking to gain a competitive edge over their rivals.

Discover more in our Case Study with Imperial Racing Green.

Hong Kong Machining Services Inc. continues to provide CNC machining services for the Film & TV industry, supplying bespoke camera parts and lens equipment.

Find out more in our case study with Sneek Films.

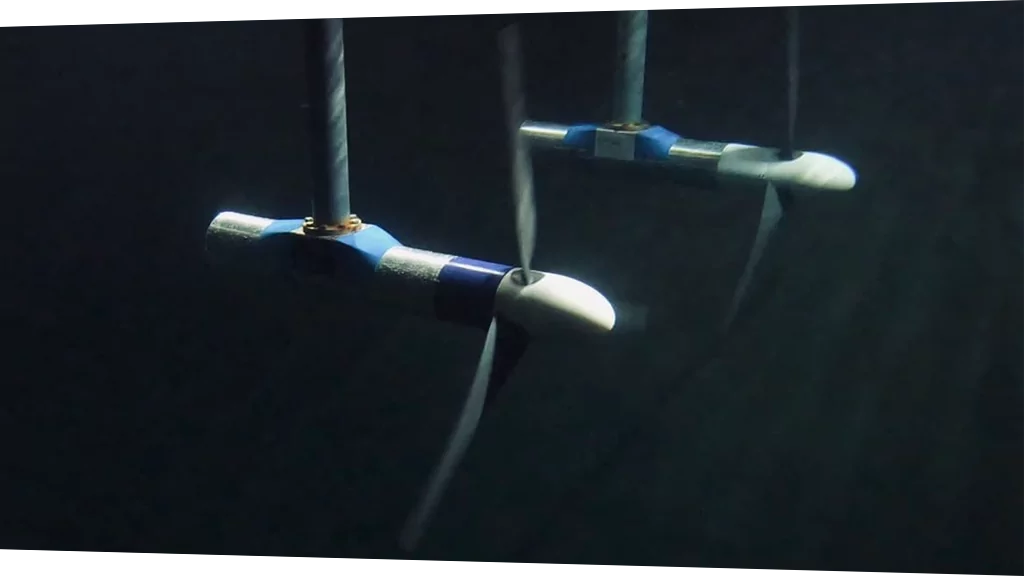

Hong Kong Machining Services Inc. is proud to supply leading HongKong Universities and scientific institutions with custom metal and plastic parts.

Read about how we helped a team from Oxford University manufacture cutting edge tidal turbines.

Find out more about our three-step process for getting your Metal Injection Moulded Parts manufactured in our How It Works video.

To begin your project, get in touch with one of our HongKong team today and we’ll get back to you as soon as possible.

When we were looking to have parts manufactured, we had tight deadlines with an even tighter budget. Hong Kong Machining Services Inc. understood our constraints and worked with us closely to get our parts to a higher standard than we expected. I can not recommend Hong Kong Machining Services Inc. enough. They are professional, communicative, and the parts are fantastic.

Ross Embleton

Head Of Research And Development - Heliguy

Hong Kong Machining Services Inc. are at the top of their game when it comes to reliability and quality. We trust Hong Kong Machining Services Inc. to deliver parts on time and within tolerance. We can't speak highly enough of their customer service. Hong Kong Machining Services Inc. are quick to reply to enquiries and keep you well informed throughout the whole process.

Max Blake

Designer - Max Blake Design

Working with Hong Kong Machining Services Inc. for all our prototyping was an absolute pleasure. Next to immediate response, fast lead times, often arriving before the stated date. Their attention to detail and customer service were second to none, and all at the most competitive price point that couldn’t be beaten in the U.K.

Ben Coughlan

Director - Sneek Films Ltd

The Hong Kong Machining Services Inc. team are very responsive and knowledgeable, fully owning a project throughout, providing superb communication. Transparent pricing structure and rapid quotation turnaround is by far the quickest I’ve experienced, reducing time to manufacture. Hong Kong Machining Services Inc. are a pleasure to work with.

Ollie Masters

Lead Process Engineer - Karakuri