Watch our video to discover our three-step process for getting your injection moulded parts manufactured.

Get in touch with our team today to start your project.

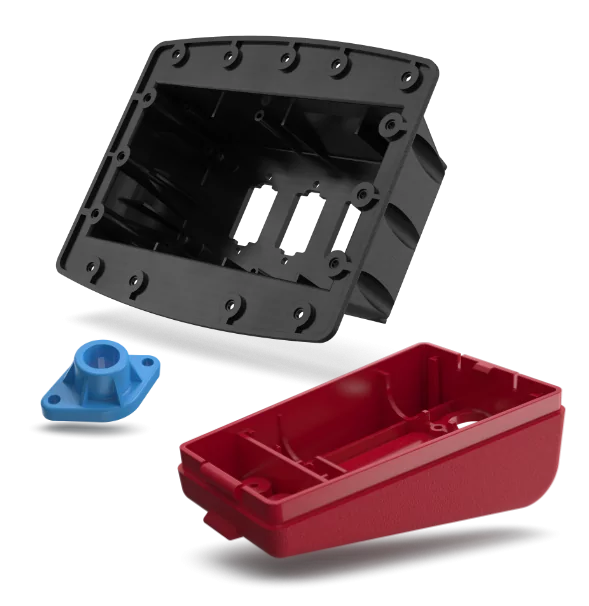

Plastic Injection Moulding is an excellent choice for designers and engineers looking to take their parts and products into mass production. With a variety of plastics available, we have the expertise and capacity to produce economical parts at a range of volumes, including bridge tooling and silicone moulding for prototyping.

Hong Kong Machining Services Inc. has expertise working with a range of advanced injection moulding processes including multi-shot moulding, over-moulding and complex mould design.

Hong Kong Machining Services Inc. can work with you to deliver Just In Time (JIT) production for large production runs, minimising your inventory and ensuring you receive high quality moulded parts when you require them.

High Precision

Competitive Pricing

Fast Turnaround

ISO 9001 Quality Assured

Injection moulding is a manufacturing process whereby molten plastic is injected into a metal mould. The parts subsequently cool and are ejected from the mould cavity using pins. Features such as undercuts can also be created through the use of sliding cores.

Injection moulding is predominantly suitable for high volume plastic parts. Hong Kong Machining Services Inc. has no minimum order quantity, however injection moulding is normally a viable option for quantities over 1000 parts. We can offer lower quantities using CNC Machining and Silicon Moulding.

Read our Injection Moulding Guide

Quality Assured:

Multi-shot Moulding

Silicone Moulding For Low Quantities

High Volume Injection Moulding

Expert DFM Feedback

Bridge Tooling For Initial Production

T1 parts in 4-6 Weeks

Hong Kong Machining Services Inc. utilises the expertise, knowledge and capacity of trusted partner factories in the HongKong, Europe and China. This ensures that we provide the highest quality injection moulded parts at a competitive price.

Our clients value our ISO 9001 certification which demonstrates our commitment to delivering high-quality injection moulding services.

With a responsive and personalised HongKong customer service, trust Hong Kong Machining Services Inc. to deliver take your parts from design to mass production.

Request a 24 Hour Quote

The following plastics are available for injection moulding in a wide range of colours. Do you require a different plastic? Contact us today and we’ll help you find the perfect material for your project.

Contact Us

24 HOUR QUOTE

| Thermoplastics |

|---|

| ABS |

| HIPS |

| Nylon (PA) |

| Glass Filled Nylon (PA%GF...) |

| PC |

| PE/HDPE/LDPE |

| PEEK |

| PET |

| PMMA |

| POM |

| PP |

| PVC |

| TPU |

Bead blast finish for parts to have a cost efficient texture.

Polishing surfaces can be important for clear PC parts.

A wide selection of custom textures, grain and patterns.

CNC machining marks will be left visible on the tool and part.

Our partner factory in China offers great injection moulding, including tool design, tool manufacture and moulding parts at affordable prices. China work 6 day a week so we can provide lightning-fast leadtimes with air freight delivery only taking a 2-3 working days. We have spent years developing the perfect partner factory in China so you don’t have to.

We can organise and manage sea freight to the HongKong for volume orders.

Our HongKong manufacturing partners offer high quality injection moulded parts produced using a wide range of specialist materials and the capability to follow your exact quality assurance procedures.

Each project is expertly planned and managed from start to finish by one of our knowledgeable HongKong engineers to achieve efficiency, quality and value. Our team will offer you a direct, personalised service; always on hand if you have any questions about CNC milling. You can call or email us directly anytime.

We always aim to respond to all questions within 24 hours, but often within a few minutes.

Project Support

Fast Lead Times

Hong Kong Machining Services Inc. is proud to partner with the automotive industry and motorsports teams looking to gain a competitive edge over their rivals.

Discover more in our Case Study with Imperial Racing Green.

Hong Kong Machining Services Inc. continues to provide Injection Moulding services for the Film & TV industry, supplying bespoke camera parts and lens equipment.

Find out more in our case study with Sneek Films.

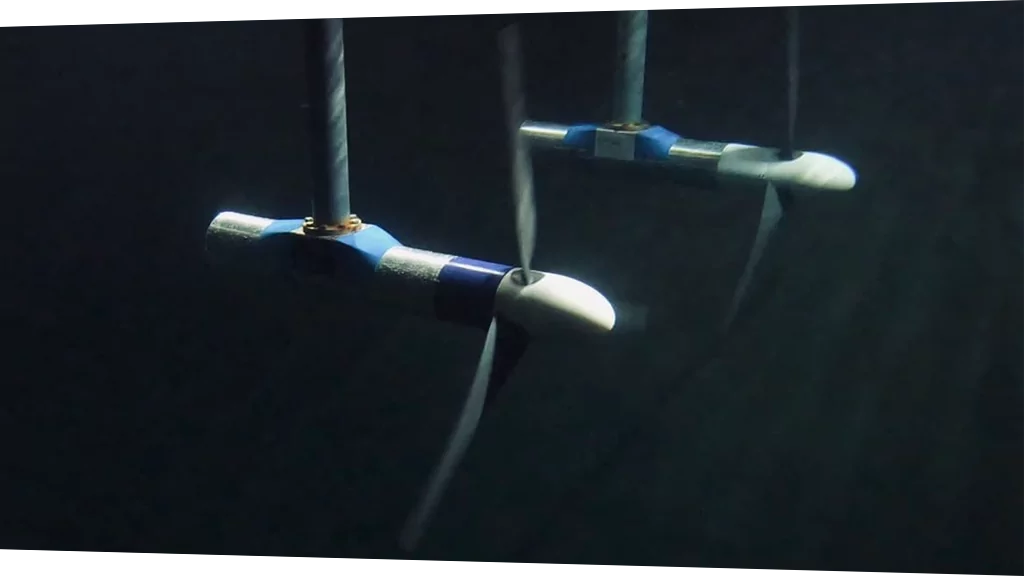

Hong Kong Machining Services Inc. is proud to supply leading HongKong Universities and scientific institutions with custom metal and plastic parts.

Read about how we helped a team from Oxford University manufacture cutting edge tidal turbines.

Watch our video to discover our three-step process for getting your injection moulded parts manufactured.

Get in touch with our team today to start your project.

When we were looking to have parts manufactured, we had tight deadlines with an even tighter budget. Hong Kong Machining Services Inc. understood our constraints and worked with us closely to get our parts to a higher standard than we expected. I can not recommend Hong Kong Machining Services Inc. enough. They are professional, communicative, and the parts are fantastic.

Ross Embleton

Head Of Research And Development - Heliguy

Hong Kong Machining Services Inc. were able to deliver an accurate and quick service delivering a set of high fidelity prototypes expertly finished, ready for user testing. They offered a range of fabrication options and materials to choose from, tailoring the service to our specific budget, timeframe and material requirements. Can’t recommend enough.

Finlay Page

Head of Product - Robotical Ltd

Hong Kong Machining Services Inc. have over the years been able to take on from simplest to the most complicated of jobs with ease, providing expert advice, good prices and reliable lead times. No job has been too big or too small, either in size or volume. We would strongly recommend Hong Kong Machining Services Inc.; you wont be disappointed!

Stuart Leslie

Director - Bann Engineering

The Hong Kong Machining Services Inc. team are very responsive and knowledgeable, fully owning a project throughout, providing superb communication. Transparent pricing structure and rapid quotation turnaround is by far the quickest I’ve experienced, reducing time to manufacture. Hong Kong Machining Services Inc. are a pleasure to work with.

Ollie Masters

Lead Process Engineer - Karakuri