A Guide to 5-Axis CNC Machining

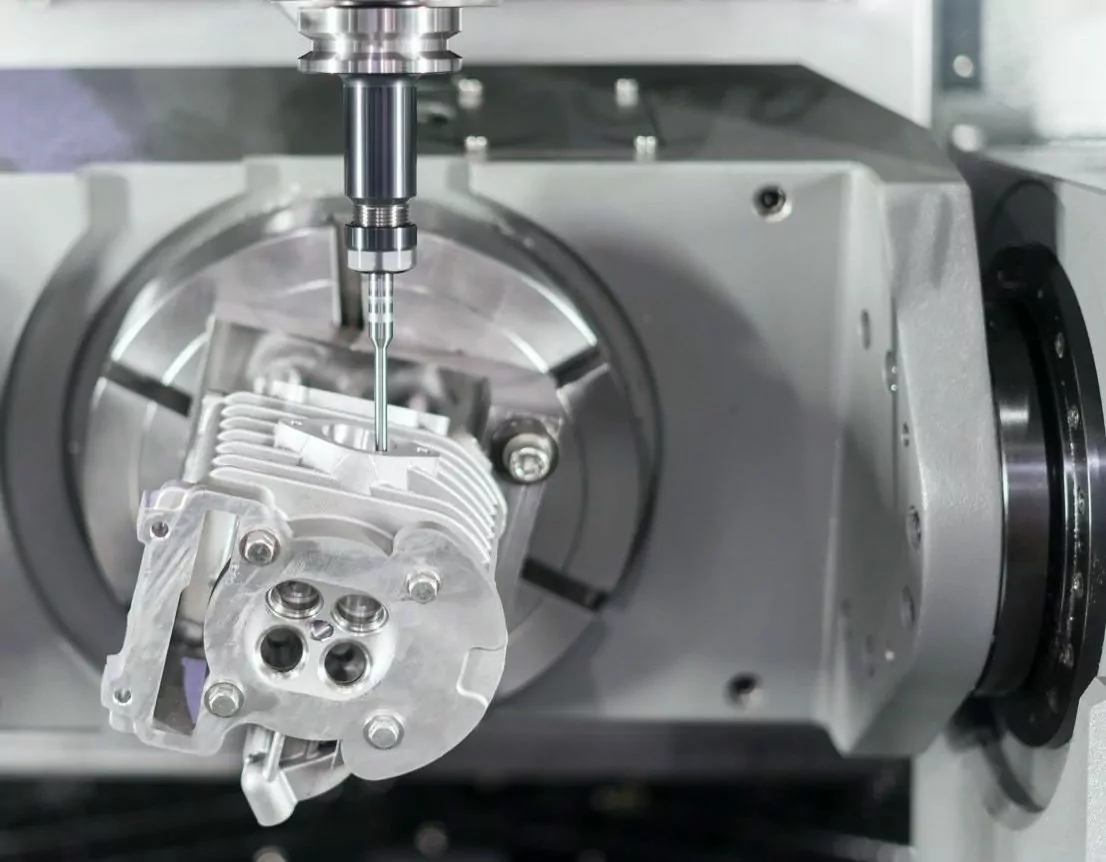

CNC machines come in a range of forms with various applications and specialities. One of these models is 5 axis machining.

What is 5-Axis CNC Machining?

As the name suggests, the machine has 5 axes which dictate the diversity of directions in which the tool can travel. Where many CNC machines operate with simply an X, Y and Z linear axis availability, 5-axis machines also incorporate A and B rotating axes upon which the workpiece can be approached from various directions.

3 + 2 CNC machines are fairly akin to 5-axis machines, however the cutting tool on a 3 + 2 is fixed into a position, as opposed to the A and B rotating axes. So, 5 axis machining refers more to the timing of function of the axes rather than their quantity. 3+2 machines possess the same number of axes, just a difference in functional ability; as well as a difference in the rotating axes, 5 axis machines are defined by their ability to perform their functions simultaneously.

How Does 5-Axis CNC Machining work?

The concept of ‘axes’ was introduced in the 17th Century by Rene Descartes who ascertained that he could describe a fly’s three dimensional location in a room using X, Y, Z variable representation; and so was born the Cartesian Coordinate system. The additional 2 axes on a 5 axis machine dictate how the A and B axes rotate around X, Y and Z. Although 6 axis machines (which have a rotating configuration for all 3 original axes) have been made, the improvements on their 5 axis counterparts are minimal. 5 axis CNC machines come in multiple forms, the most common of which being:

- Drop swivel head

- Drop table

- Double swivel head

- Double swivel table

- One swing one rotate

The main difference between the types of 5 axis machines is where on the machine the rotational axes appear. 5 axis machines can either have the rotation found in swivelling the tool head against a still material or moving the table and, therefore, the object. Swivel head machines can facilitate a larger and heavier object since it does not have to manoeuvre the object at hand, whereas a rotating table machine can provide stability and speed for materials with less weight.

Some more precise examples of these machines are:

- Swivel head with rotary table – this machine has a large table which allows for heavy objects whilst maintaining versatility due to the space on the table which can be used to finish the 6th side of the object or carry out 3 axis work. The swivel head on this machine helps to avoid tool interference with the spindle head

- Trunnion table design – The rotation degree on this machine provides better undercut capability whilst facilitating larger work volume since you don’t need to compensate for the space that a swivel head tool takes up. The stationary spindle also allows for more low end torque because it is belt-driven

- Travelling column design – This machine is more rigid, which makes it more stable due to minimised movement. This helps to promote repeated accuracy and repeatability of design

Why 5-Axis CNC Machining?

5-axis CNC machining allows the machine to execute complex and intricate tasks by engaging all 5 axes simultaneously providing the following benefits:

- Minimised production time; the ability to complete a project in one multidimensional function necessitates less prep and production time

- Rotating A and B axes promote tool health and longevity by reducing the likelihood of collision whilst facilitating optimal tool angles against the material, avoiding unnecessary wear

- Broadened opportunities for the geometric variety and capacity of projects: the more mobile the axes upon which a tool can move, the more diverse the possibilities of production

That being said, there are still many uses for 3 axis and 3 + 2 CNC machines. Finding the right CNC machine is truly dependant on the job at hand and which functions your blueprint requires. If your project demands are simple and call for relatively low cost, then employing a 5 axis machine could be like cutting butter with a carving knife; as 5 axis machines tend to be used for industries who require extremely high levels of accuracy and detail such as automotive, medical and aerospace. There are tonnes of CNC machine variations for that reason – each machine serves its own purpose and has varying benefits for different operations. This is why it’s important to discuss your requirements with a professional to find out which machine is best for you and your needs.

Get in touch with Hong Kong Machining Services Inc. today to begin your 5 Axis CNC Machining project.