12

Jul

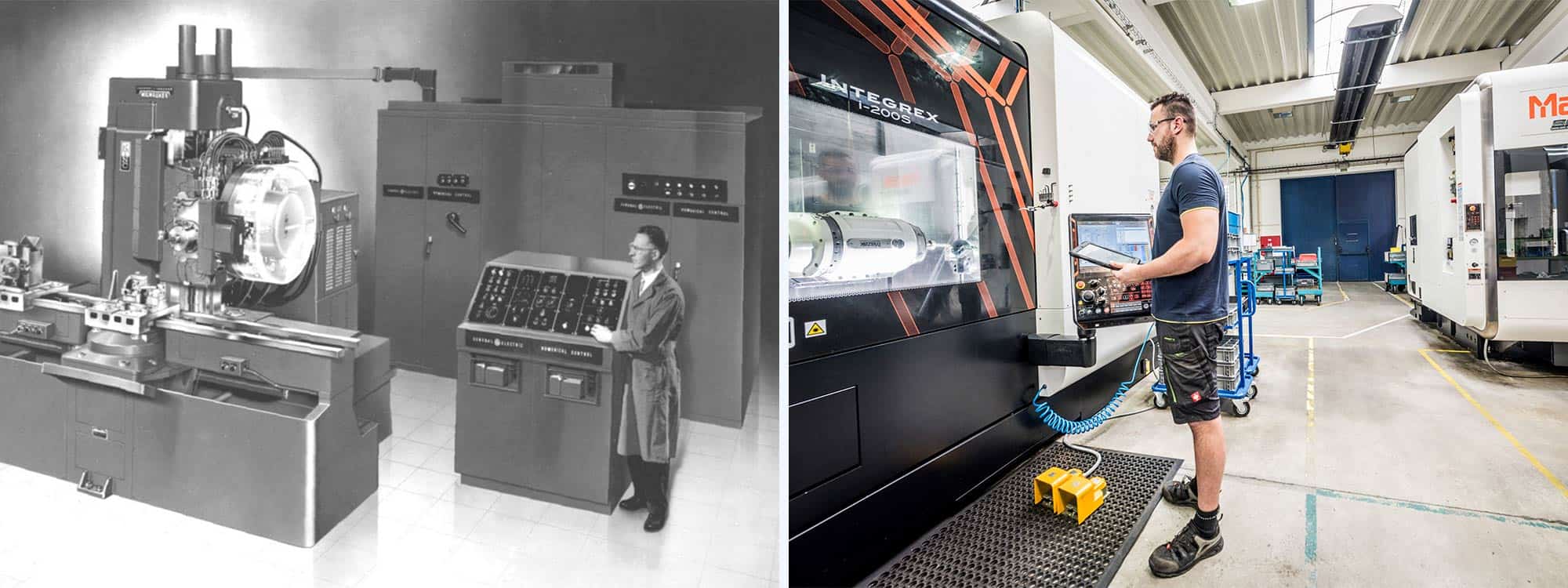

The History of CNC Machining

What does CNC stand for?

CNC stands for Computer Numerical Control. In essence this refers to a computer supplying a series of numerical coordinates and information to a machine in order to control the function of the machine. Fortunately, there is a standardised language across many CNC machines called G Code. G code allows computers and machines to talk to one another and communicate information such as tool location in the X, Y and Z axes, spindle speeds and much more.

When did CNC machining start?

Although humans have been using tools to harness and accentuate power for 2.6 million years, the true machining development came with the industrial revolution. The industrial revolution commenced in the 18th century, and was a reformation of the manufacturing industry. With the introduction of machines, the potential production rate skyrocketed whilst the production time was drastically minimised. During this time, employment rates in factory work were on the rise, as were the work hours. It wasn’t until 1833 that the Factory Act enforced capped work hours for children, setting a standard for factory work and subliminally marking an acknowledgement of the level of human demand. The Factory Act led manufacturers and machinist to pursue options that reduced the need for human input, in doing so, paving the way for automated machining methods.

Punch tape method

Despite the substantial leap forwards in terms of quality and uniformity in manufacturing, there was still room for human error, as a result of the level of input required by factory workers. This bore the idea of a completely automatic numerically controlled machine line so as to relieve the requirement for so much human input and supervision. The first conception of this notion was established by John T Parsons, who developed the idea of Numerical Control (NC) machines using punched tape. This was a way to store numerical data by punching holes in long tape, read by paper tape reader and translated to machines for the instructed work to be carried out. In 1949 the Air Force funded Parsons to bring to life this first draft of NC machining, creating a machine with motorised axes to aid the production of helicopter blades, programmed by the punch tape method. Not long after, MIT collaborated with Richard Kegg to conceive the first numerically controlled milling machine.

In 1955, the punch tape method evolved to use a magnetic tape reader and more versatility in machine functions. This process began with planner sheet where the direction variable such as speed, cooling control and feeds, etc., could be entered. Then, instructions were input via keyboard into a unit which converted the information from decimal form into a plastic tape. Parity checks informed the system of any incorrect readings and another system would check that the parity system was functional. The tape was then fed into a digital reading unit which translated the information into a computer, whereby the computer would send instructions to the machines to direct them in the execution of tasks.

The rise of the CNC machine

The introduction of digital technology in the 1960s and 1970s forged numerical control machines more similar to those we use today: CNC (computer numerical control) machines. This marked the evolution from punched tape to digital software, which operates under the same principals as NC machining but has more capacity for technological advancement. The software which replaced punch tape is referred to as CAD (Computer Aided Design) software and, after some updates and retrofitting, is what we use today. CAD software allows (people) to create a blueprint on a computer which is translated into a CNC–legible format called G-code, which directs the CNC machine to operate across specific axes and motions. CAD software allows for accelerated production of designs, easier revisions and the capability for endless software revisions and updates, ensuring that CNC machining is a sustainable and forward-thinking manufacturing investment.

CNC machining by industry

Fast forward to the 21st century and CNC Machining and CNC Machined parts are prevalent in the vast majority of industries. Particular industries that rely on CNC Machining include the aerospace industry, robotics industry and the medical industry. This trend is set to continue with industries such as Green Energy set to boom over the next decades. As products and machines require ever increasing efficiency and reductions in size, CNC machining provides engineers and designers with high-precision parts that meets the demands required.

How much does CNC machining cost?

CNC machining costs naturally vary depending on the complexity and quantity of parts. Whilst it is hard to place a precise cost on CNC Machining, it is known for having relatively low setup costs compared to other processes such as injection moulding. Typically CNC Machining is a viable manufacturing process for quantities of 1x to 10000x. Beyond these quantities, consider aluminium die casting or plastic injection moulding.

CNC Machining Guide

Hong Kong Machining Services Inc. has many years experience producing CNC parts across a wide range of industries. Find out more about CNC Milling and CNC turning in our how-to guides which will help you avoid common design pitfalls.

Ready to start your project? Request a quote today and one of our knowledgeable HongKong-based team will personally review your project.