7

Sep

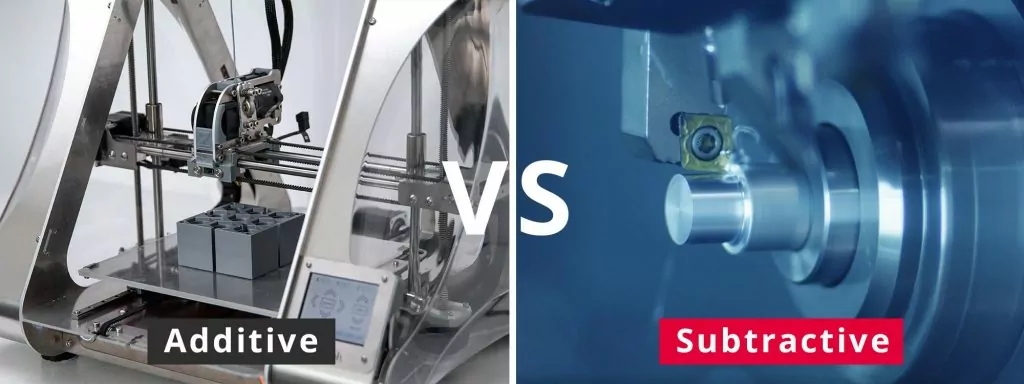

Additive VS Subtractive Manufacturing

Overview

Additive and subtractive manufacturing both function via CAD (Computer Aided Design) software. Both forms of manufacturing can be highly accurate and used for intricate designs for various industries and uses. Both have their niches and benefits for specific aims, which we will delve into below.

Additive Manufacturing

The world of additive manufacturing is ruled by 3D printers. 3D, much like the name suggests, operate by printing layers of material, rather than detracting from a pre-existing object. This function is called fused depositional modelling and works by the machine repeatedly depositing over the same area to build from the base upwards to create the final model. So, although it is called a 3D printer, it actually prints each layer in 2D cross-sectional layers which are essentially stacked upon one another until the desired design has been produced.

Normal printers use either powder or ink to create their marks on paper but of course these substances would not suffice in building a 3D design. In most 3D printing, each layer is born of molten thermoplastic and then fused together either using adhesive or ultraviolet light. Thermoplastics are a type of plastic whose form depends on their temperature – when heated, they become liquid and when cool they return to solid form. This of course does mean that during the process of 3D printing, the machine must wait for each layer to cool before depositing the next, in order to preserve the integrity of the shape.

While the most common material used with 3D printers is plastic, some also function using metal. These printers still function with the same layer-by-layer process of 2D sections; however they use blankets of metal powders in place of their plastic material counterparts.

Subtractive manufacturing

Subtractive manufacturing begins with a block of material and cuts away at it in order to reveal and create the desired part. CNC machines dominate the subtractive manufacturing realm and come in myriad forms to cover an array of demands. Like 3D manufacturing, CNC machining can be used with plastic and metal but works with them in their solid raw forms.

CNC machines work in various ways, they can either have manoeuvring and rotating tools being introduced to a still material which is held in place or the object itself can be rotated by the machine. Again, this is project dependent. CNC machines can work on a variety of materials from metal and plastic to wood and come in all shapes and sizes, learn more about types of CNC machines and their functions here.

Which is best?

Subtractive and additive manufacturing are good for different purposes, but when it comes down to it there is no use in employing a 3D printer to manufacture work which is meant for CNC machines. For example, 3D machines need a fairly specific metal type to achieve optimal functionality, which results in less versatility and leeway in terms of which materials you can use for metal based projects. They also don’t offer the same value for money when it comes to large scale production because the necessity for them to wait for each layer of material to dry causes a time delay. CNC machines, however, can complete multiple functions simultaneously if needed. So, if you’re looking for the optimal value for money whilst maintaining the integrity, detail, quantity, quality, speed and diversity of material possibilities – you’re best off investing in CNC machining.

Hong Kong Machining Services Inc. is proud to offer a wide range of both additive and subtractive manufacturing processes including CNC Milling and CNC Turning. Get in touch to discuss your project and to arrange a quote.